-

Q: Why you should use Roller Burnishing Tool (Roller Burnishing Tool Functions)?

A:

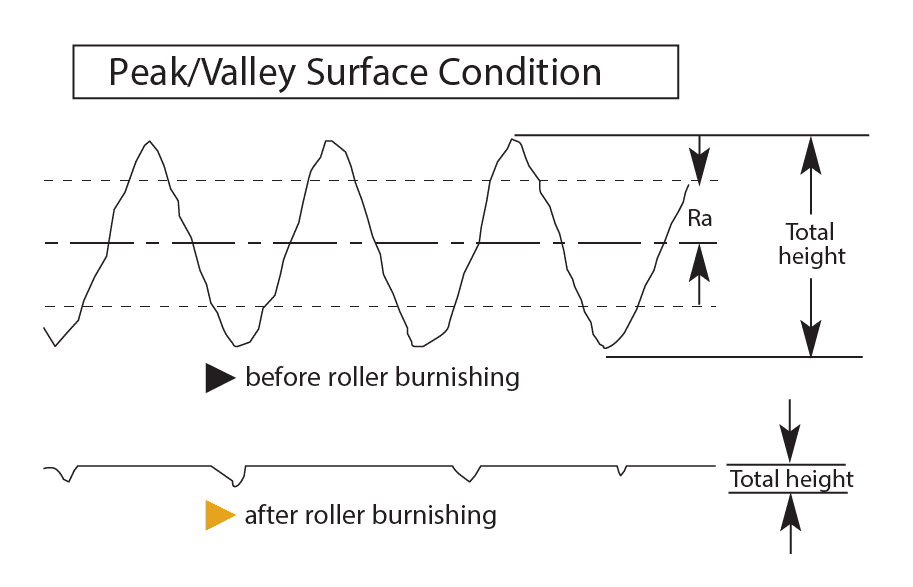

Peak/Valley Surface Condition Draft

- 1.

Roller burnishing is a surface finishing technique in which hardened, highly polished steel rollers are brought into pressure contact with a softer piece part. As the pressure generated through the rollers exceeds the yield point of the piece-part material, the surface is plastically deformed by cold flowing of sub-surface material. The result is a mirror-like finish and a tough, work-hardened surface with load-carrying characteristics which make the burnished surface superior to finishes obtained by abrasive metal-removal methods. - 2.

A roller burnished surface is smoother and more wear-resistant than an abraded surface of the same profilometer reading. Profilometers measure roughness height. Abrasive finishing processes remove metal by cutting or tearing it away, and while this usually lowers the roughness profile, it leaves sharp projections in the contact plane of the machined surface. - 3.

Roller burnishing displaces metal, rather than removing it. Material in microscopic “peaks” on the machined surface is caused to cold flow into the “valleys,” creating a plateau-like profile in which sharpness is reduced or eliminated in the contact plane. A burnished surface is therefore smoother than an abraded surface with the same roughness height measurement. The burnished surface will last longer under working conditions in contact with a mating part.

-

Q: Why choose RBT as your supplier?

A:

- 1. High Quality:

We choose brand parts on products, which ensures each product pass several different country’s test and get certification for customer. - 2. Newest Design:

Every year we customize the special purpose machine according to customer’s products at least 150 different types. - 3. Our advantage:

Have our brand and product patent.

Product certification for different countries.

With BV, SGS, BSCI factory inspection.

Use brand accessories.

High quality product with good price.

Professional after-sale service team.

-

Q: Are you trading company or manufacturer?

A: We are factory and with our own R&D team.

-

Q: Can I get some samples?

A: Sure, samples are available. Please contact us for more details.(service@rbtburnishingtool.com)

-

Q: How can I pay for the samples?

A: T/T in advance, Credit Card, Cash, PayPal , L/C , D/P D/A;

-

Q: How long about the delivery time?

A: 30 days after receiving the deposit or L/C.

-

Q: Can you manufacture the customized products as I wish?

A: Yes, we can. OEM & ODM are available.

-

Q: What are your terms of delivery?

A: We accept FOB, CFR, CIF etc. You can choose the one which is the most convenient or cost effective.

-

Q: What is the terms of payment?

A: 30% T/T deposit, the balance before delivery.

-

Q: Have I get warranty on your products?

A: 1 years after shipment.

-

Q: What kind of files do you accept for drawing?

A: PDF, Core Draw, high resolution JPG.

-

Q: What about the lead time for mass production?

A: Honestly, it depends on the order quantity and the season you place the order. Generally speaking, production lead time is within 35-45 days.