Advantages of roller burnishing

It is safe, convenient and accurate to control precision.

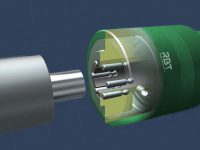

Roller burnishing tools advantages are:

- 1. Improve the surface roughness, and the roughness can basically reach the Ra less than 0.08um.

- 2. Correction of roundness, the ellipticity can be less than 0.01mm.

- 3. Improve the hardness of the surface to eliminate the deformation of the force and increase the hardness of HV to 40.

- 4. After processing, the residual stress layer and fatigue strength increased by 30%.

- 5. Improve the quality, reduce wear, and prolong the service life of the parts, but the processing cost of the parts is reduced.

Roller burnishing tool application advantages – The effect after burnishing

High efficiency – a few seconds can process the surface to the desired surface precision, the efficiency is 5-20 times of grinding and 10-50 times more than the turning.

High quality – the mirror accuracy of the first step in the realization of Ra0.05-0.1um; The surface is extruded and hardened, wear resistance and fatigue strength are improved. The dimensional precision can be stable for a long time.

Economy – no need for large equipment capital, land, power consumption, waste disposal and other inputs; You don’t need a professional mechanic.

Convenient – can be installed in any rotation and feed equipment, without professional training can process the burnishing precision.

Environmental protection – no chip (protection), low energy consumption.

Safety – no cutting tool without cutting edge.

We are Manufacturer, Exporter, Supplier and Trader of Roller Burnishing Tools. Offered to the customers is a high quality range of Roller Burnishing Tool as per their specific requirements.