How Integrated Drilling, Chamfering and Deburring Tools work?

During processing with the Integrated Drilling and Deburring Tool, First step, a through-hole is drilled through the drill bit and drill bit centering. Second step, upon entry, spring tension holds the cutting blade in the extended position as it removes the burr on the front of the hole. Third step, as the feed load increases, the pre-set spring tension is exceeded and the blade retracts automatically as the tool passes through the workpiece. Fourth step, spring tension again causes the blade to extend as it emerges from the ID of the part; the burr is removed on the back side of the hole on the return stroke.

Today, a client from Chennai, India; who asks RBT that whether we have the integrated tools for drilling, chamfering and deburring in one-pass. His requirements are machining a small size hole in a tube of EN8 steel, as below:

Workpiece Materials: EN8 Steel

Workpiece Hardness: Standard Hardness

Workpiece Diameter: 38 mm

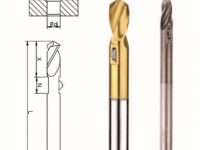

RBT solutions: A special & customized drilling and deburring tool from RBT burnishing tool is Integrated Drilling, Chamfering and Deburring Tool. The product image is: