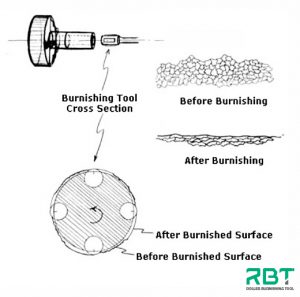

Roller burnishing has long been used on a wide variety of automotive and heavy equipment components (construction, agricultural, mining and so on), including piston and connecting rod bores, brake system components, transmission parts and torque converter hubs.

Burnishing tools are now widely used in non-automotive applications to achieve a variety of benefits: to create a better, more durable seal surface; Increased wear life; Reduce friction and noise level of running parts; And enhance the appearance; to improve wear life; to reduce friction and noise levels in running parts; and to enhance cosmetic appearance. Examples include valves, pistons for hydraulic or pneumatic cylinders, lawn and garden equipment components, shafts for pumps, shafts running in bushings, bearing bores, and plumbing fixtures.

RBT Roller Burnishing Tools are used for the aim of burnishing the cylindrical holes that have an open and closed end. The tools provide as well as surface hardness and calibration (measurement accuracy) beside of burnishing. According to the process type, there are three types of RBT burnishing tools:

RBT roller burnishing tool applications

Blind Hole machine-feeding

These burnishing tools process stepped or fully closed holes up to end. While the tools process the workpiece, the machine provides feeding speed which is needed.

Through Hole machine-feeding

These burnishing tools process the holes with open ends. The machine provides the required feed speed when the tool is working on the workpiece.The tool or the workpiece can be turned with the speed of max. 250 m/min. The feeding speed of the machine can range from 0,05 mm/rev. to 0,3 mm/rev. for per roller.

Through Hole self-feeding

These burnishing tools process the holes with open ends. The tools provide own feeding speed which is needed while it is processing the workpiece. Feeding occurs free from the machine.

Why choose RBT?

We have emerged as a highly reliable Manufacturer, Exporter and Supplier of Roller Burnishing Tools in China. We can offered to the customers is a high quality range of Roller Burnishing Tools as per their specific requirements.

Our Roller Burnishing Tools are made using high-grade raw material, at the vendors’ end. Our product range is highly demanded in the market for its hassle-free work performance the users’ premises.