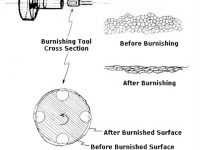

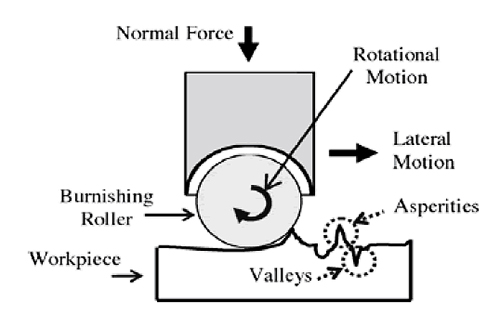

The roller burnishing tools works like a road roller flattening the uneven road.

Roller burnishing tool is to use very smooth roller rolling by processing the surface of the metal, the workpiece performance high extrusion convex parts to dips, so that the machining surface smooth as a mirror effect, this is a kind of plastic processing.

The surface roughness of workpiece is up from Ry1.6-3.2 um to Ry0.1-0.2 um, and improve the processing surface hardness, wear resistance, corrosion resistance, sealing, etc., to eliminate early wear, these have the advantage of machining cannot be replaced.

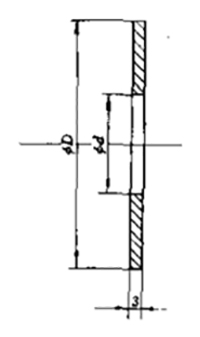

The rolling tool has a fine tuning device. The adjustment coefficient of each small grid is 0.0025mm, and the total adjustment range is 0.3mm-0.4mm. Therefore, the precision of the processed dimension is also improved accordingly.

The control method of roller burnishing tools

1. Measuring the burnishing tool’s diameter with micrometer.

2. Push the calibrated set to the handle and rotate it at the same time, adjust the diameter of the tool, reduce the left rotation, and increase the right rotation, each scale value is 0.0025mm.

3. When the diameter is adjusted, release the aluminum shell and automatically lock the diameter.

4. When machining blind holes and step holes, the bottom is about 0.5mm-1.0mm cannot be machined. The needle can lightly touch the bottom of the hole.

Processing equipment

We are roller burnishing tools suppliers. RBT roller burnishing tools are suitable for common drilling machine, lathe, boring machine and machining center.

The clamping forms of tools include: straight shank and Morse taper shank. It can also be made according to customer needs.

Our Roller Burnishing Tools are made using high-grade raw material, at the vendors’ end. Our product range is highly demanded in the market for its hassle-free work performance the users’ premises.

If you do not know how to choose the model of the burnishing tools, you can contact us. We have professional customer service staff to help you find the most suitable product.