Roller burnishing improves surface finish by removing scratches, tool marks and pits and induces beneficial compressive surface residual stresses. Consequently, corrosion performance is improved because corrosion products and residues cannot be entrapped. In this process known as low – plastic grinding, the rollers move only once on the surface, resulting in residual stresses and minimal plastic deformation. Internal cylindrical surfaces also are burnished by a similar process, called ballizing or ball burnishing. In this process, a smooth ball is pushed through the length of the hole.

Benefits of RBT Roller Burnishing Tools

Roller burnishing is used to improve the mechanical properties of surfaces as well as their surface finish. It can be used alone or in combination with other processing techniques such as grinding, honing, and lapping. The equipment can be installed on various CNC machine tools to improve productivity and consistency. All types of metals can be roller burnished.

Roller burnishing is typically used on hydraulic system components, seals, valves, spindles, and fillets on shafts.

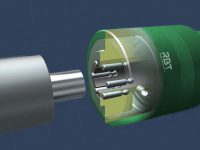

Multi-roller burnishing tool: Impressive advantages

- Hardened boundary layers

- Increased fatigue strength

- Greater surface resistance to wearing and corrosion

- Shifting of the material fatigue Limits

- Equire very short machining times

- Realize outstanding surface qualities

- Reduction of coefficients of sliding friction

- Environmental friendliness due to a lack of waste products