Description

RBT universal micro deburring tools, chamfering & deburring tools, universal deburring tools, One-piece Construction & Single Cutting Edge

One Simple Setscrew Adjustment

Controls Depth of Cutting

Releases Blade for Hand Replacement

SIMPLE-PIECE DEBURRING TOOLS – UNIVERSAL DEBURRING TOOLS

Economical deburring tool of holes for the front, back or both sides in one pass.

Video of Deburring Tool (One-piece Construction)

Specifications of Deburring Tools

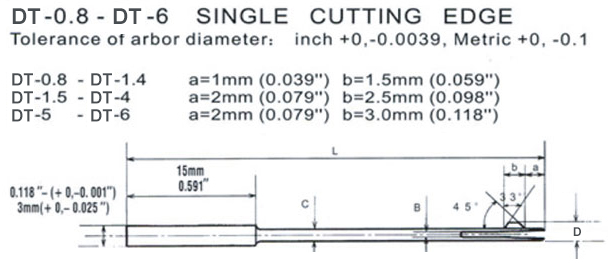

RBT single cutting edge of Chamfering and Deburring Tools

| Tool Model | RANGE HOLE SIZES | ARBOR DIAMETER(C) |

OVERALL LENGTH(L) |

DIMENSION

|

DIMENSION

|

DIMENSION

|

ROTATE SPEED(RPM) |

|---|---|---|---|---|---|---|---|

| RBT-DT-0.8 | 0.8-0.9 | 0.7 | 45 | 1 | 1.5 | 1.05 | 1800 |

| RBT-DT-0.9 | 0.9-1.0 | 0.8 | 45 | 1 | 1.5 | 1.2 | 1800 |

| RBT-DT-1.0 | 1.0-1.1 | 0.9 | 45 | 1 | 1.5 | 1.35 | 1800 |

| RBT-DT-1.1 | 1.1-1.2 | 1.0 | 45 | 1 | 1.5 | 1.5 | 1800 |

| RBT-DT-1.2 | 1.2-1.3 | 1.1 | 45 | 1 | 1.5 | 1.65 | 1800 |

| RBT-DT-1.3 | 1.3-1.4 | 1.2 | 45 | 1 | 1.5 | 1.8 | 1800 |

| RBT-DT-1.4 | 1.4-1.5 | 1.3 | 45 | 1 | 1.5 | 1.95 | 1800 |

| RBT-DT-1.5 | 1.5-1.6 | 1.5 | 50 | 2 | 2.5 | 2.1 | 1500 |

| RBT-DT-1.6 | 1.6-1.7 | 1.5 | 50 | 2 | 2.5 | 2.25 | 1500 |

| RBT-DT-1.7 | 1.7-1.8 | 1.6 | 50 | 2 | 2.5 | 2.4 | 1500 |

| RBT-DT-1.8 | 1.8-1.9 | 1.7 | 60 | 2 | 2.5 | 2.55 | 1500 |

| RBT-DT-1.9 | 1.9-2.0 | 1.8 | 60 | 2 | 2.5 | 2.65 | 1500 |

| RBT-DT-2 | 2.0-2.2 | 1.9 | 60 | 2 | 2.5 | 2.8 | 1500 |

| RBT-DT-4 | 2.2-2.4 | 2.1 | 80 | 2 | 2.5 | 3.15 | 1500 |

| RBT-DT-5 | 2.4-2.6 | 2.3 | 80 | 2 | 2.5 | 3.45 | 1500 |

| RBT-DT-6 | 2.6-2.8 | 2.5 | 80 | 2 | 2.5 | 3.7 | 1500 |

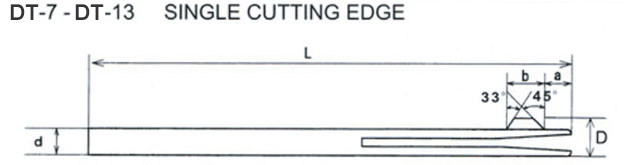

RBT single cutting edge of Chamfering and Deburring Tools

| Tool Model | RANGE HOLE SIZES | ARBOR DIAMETER(d) |

OVERALL LENGTH(L) |

DIMENSION

|

DIMENSION

|

DIMENSION

|

ROTATE SPEED(RPM) |

|---|---|---|---|---|---|---|---|

| RBT-DT-7 | 2.80-3.18 | 2.75 | 101.6 | 3.18 | 4.45 | 4.00 | 1200 |

| RBT-DT-8 | 3.18-3.56 | 3.15 | 101.6 | 3.18 | 4.45 | 4.34 | 1200 |

| RBT-DT-9 | 3.56-3.96 | 3.58 | 101.6 | 3.18 | 4.45 | 4.75 | 1200 |

| RBT-DT-10 | 3.96-4.37 | 3.94 | 101.6 | 3.18 | 4.45 | 5.54 | 1200 |

| RBT-DT-11 | 4.37-4.78 | 4.34 | 101.6 | 3.18 | 4.45 | 5.94 | 1200 |

| RBT-DT-12 | 4.75-5.16 | 4.72 | 101.6 | 3.18 | 6.22 | 6.35 | 1200 |

| RBT-DT-13 | 5.16-5.56 | 5.13 | 101.6 | 3.18 | 6.22 | 6.78 | 1200 |

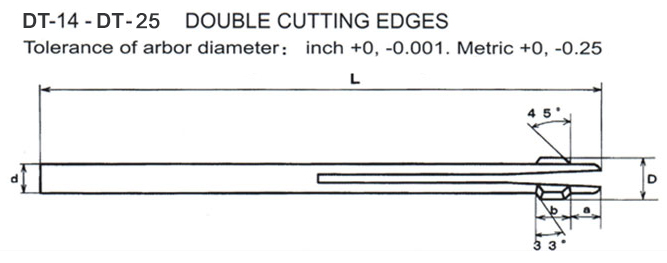

RBT double cutting edges of Chamfering and Deburring Tools

| Tool Model | RANGE HOLE SIZES | ARBOR DIAMETER(d) |

OVERALL LENGTH(L) |

DIMENSION

|

DIMENSION

|

DIMENSION

|

ROTATE SPEED(RPM) |

|---|---|---|---|---|---|---|---|

| RBT-DT-14 | 5.56-5.94 | 5.54 | 101.6 | 6.48 | 6.22 | 7.92 | 800-1000 |

| RBT-DT-15 | 5.94-6.35 | 5.92 | 101.6 | 6.48 | 6.22 | 8.33 | 800-1000 |

| RBT-DT-16 | 6.35-6.76 | 6.32 | 101.6 | 6.48 | 6.22 | 8.71 | 800-1000 |

| RBT-DT-17 | 6.76-7.14 | 6.73 | 101.6 | 6.48 | 6.22 | 9.12 | 800-1000 |

| RBT-DT-18 | 7.14-7.54 | 7.11 | 101.6 | 6.48 | 6.22 | 9.53 | 800-1000 |

| RBT-DT-19 | 7.54-7.95 | 7.52 | 101.6 | 7.24 | 6.48 | 9.91 | 800-1000 |

| RBT-DT-20 | 7.95-8.33 | 7.92 | 101.6 | 7.24 | 6.48 | 10.31 | 800-1000 |

| RBT-DT-21 | 8.33-8.74 | 8.31 | 101.6 | 7.24 | 6.48 | 10.72 | 800-1000 |

| RBT-DT-22 | 8.74-9.12 | 8.69 | 101.6 | 7.24 | 6.48 | 11.10 | 800-1000 |

| RBT-DT-23 | 9.12-9.53 | 9.09 | 101.6 | 7.24 | 6.48 | 11.51 | 800-1000 |

| RBT-DT-24 | 9.53-9.93 | 9.50 | 112.7 | 8.00 | 6.48 | 12.70 | 800-1000 |

| RBT-DT-25 | 9.93-10.31 | 9.88 | 112.7 | 8.00 | 6.48 | 13.08 | 600 |

The Simple-piece Deburring Tool is a simple one-piece construction, but is designed for high-production, automated deburring operations. The open-slot design allows chips to clear easily, which suits for automated processes in series machines. The Simple-piece Deburring Tool can be deburred the front, back, or both sides of holes in one fast pass with long service life.

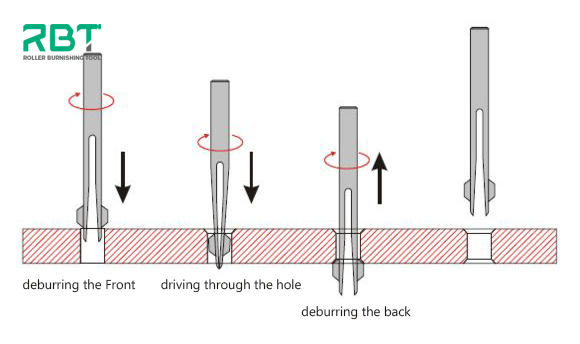

HOW UNIVERSAL DEBURRING TOOLS WORK?

How RBT universal deburring tools works?

1. Feed-in

Integrated cutting edges remove the burr from the front of the hole as the tool enters the hole. The tool deburrs the hole under spring pressure.

2. Feed-thru

During passing through the bore, the cutting edge is pushed under spring tension into the tool; the slotted design allows the tool to shrink under load as the tool feeds through the workpiece. (The crowned and polished top surface of the cutting edges will not mar the inside surface of the hole)

3. Feed-out

In the work feed backwards the back of the hole is deburred.

As the return stroke of deburring tool, the hole is deburred on the back side.

FEATURES:

- Easy to use on all machines

- Changing the direction of rotation is not needed

- Effective tool, can be regrounded up to 4 times

- Nochip congestion through the open slot design

- Fromdeburring Ø 56 mm with 2 cutting edges

- Deburring thickness can be adjusted through the adjusting screw

- Standard toolsfrom Ø 57 mm to 16.28 mm from stock

Reviews

There are no reviews yet.